Munia is a 6th grade student at Bawniabad Adolsho Uchaya Bidaroy School, a GENKI program affiliated school located in a slum in the Mirpur district of the capital Dhaka. She lives near the school with her parents and two older sisters who go to the same school.

(left) / With classmates in the classroom (Munia is in the front row right) (right)

The tuition fees for the three children total about 3,000 yen per month. His father works as a rickshaw (three-wheeled taxi) driver, but his monthly income is about 14,000 yen, which is not enough to support the family. So Munia’s mother, Honufa, decided to help her by learning how to make shoes from her older brother, Mokhtar, who runs a small shoe workshop. She makes parts for about 24 pairs of shoes a day and earns about 3,000 yen a month.

In addition to making shoes, Honufa also has to do household chores, so there are times when delivery times are not met. Munia decided to help her mother after school. She’s a fun job for Munia, who dreams of becoming a shoe designer.

Munia is learning how to make shoes from Moktar’s son and cousin Raihan. Raihan is a ninth grader who attends the same school as Munia, and he also helps out with shoemaking at Moktar’s workshop. Raihan carefully teaches Munia how to embed various designs and parts of shoes.

Raihan working in the workshop (right)

After receiving an order for shoes from a client retailer, Ms. Moktar first procure materials such as leather, laces and decorations at a market in Dhaka city. Once the materials are ready, the leather parts are cut according to the wooden pattern. Hand over the cut parts to Munia-chan’s parent and child, and attach parts such as beads. Once finished, sew the upper part of the shoe and secure it to the sole. It’s all manual and painstaking work.

It is never easy to balance studying and helping with the family business. Munia’s school is from 8am to 1pm. After Munia returns home, she helps her make shoes while the sun is shining. Munia’s house is dimly lit, and she can’t do the detailed work of attaching parts such as beads. After making shoes, you can study at night. Still, Munia is positive. She said, “When I help her make shoes, I think she’s getting closer to her dream of becoming a designer. Her mother and teachers are very supportive of me. That’s why she can study hard and help out.” told me.

The GENKI program will continue to support children.

2. Participation of new co-sponsoring partner companies

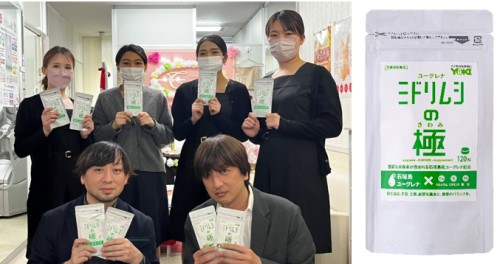

The GENKI program uses a portion of the product sales of the Euglena Group and partner companies as sponsorship money. As of the end of November 2022, 11 partner companies have participated and have contributed 10 yen for each target product sold. And this time, from December 2022, Yuki Co., Ltd. will newly participate as a partner company.

Yuki Co., Ltd. develops and sells health foods and beauty products based on the concept of “Making People and the Earth Smile”. We use sustainable materials and provide products that are in harmony with nature. In addition to solving customers’ health and beauty issues, we also contribute to social and environmental issues, aiming for a sustainable future.

In the future, we will continue to strive to expand the GENKI program with the aim of improving the nutrition of children in Bangladesh so that we can give shape to the ideas of our partner companies.